Kinh nghiệm bắt lô và phương pháp chơi hiệu quả được anh em lô thủ chia sẻ rộng rãi trên các diễn đàn giúp tham khảo, để đưa ra được phương pháp soi cầu lô đề dễ trúng nhất. Trong bài viết này, Fi88 Link sẽ tổng hợp và chia sẻ thêm các cách đánh lô theo ngày hiệu quả nhất, dựa trên kinh nghiệm của được tích lũy từ trước để anh em tham khảo nhé!

Kinh nghiệm bắt lô và phương pháp chơi chuẩn nhất

Trước khi muốn biết kinh nghiệm bắt lô và phương pháp chơi hiệu quả là gì, anh em cần phải hiểu rõ thuật ngữ chơi đánh đề là như thế nào. Đánh lô được hình thành từ rất sớm, từ những giai đoạn đầu của xổ số kiến thiết.

Hướng dẫn chơi xổ số miền bắc rất đơn giản, nếu anh em đặt cược và dự đoán chính xác 2 số cuối giải đặc biệt thì anh em sẽ trúng thưởng. Tỷ lệ trả thưởng nếu anh em chơi thực tế bên ngoài thường là 1 ăn 70 đến 80. Tuy nhiên nếu anh em chơi ở những nhà cái uy tín thì tỷ lệ ăn là 98-99%. Cao hơn nhiều so với lối chơi truyền thống phải không?

Kinh nghiệm bắt lô hiệu quả

Sau đây, mình sẽ giới thiệu đến anh em những kinh nghiệm bắt lô và phương pháp chơi hiệu quả để anh em có thể tham khảo đưa vào cách chơi của mình sao cho hợp lý nhé.

Giải 7 lấy số trùng đầu trùng với số đuôi

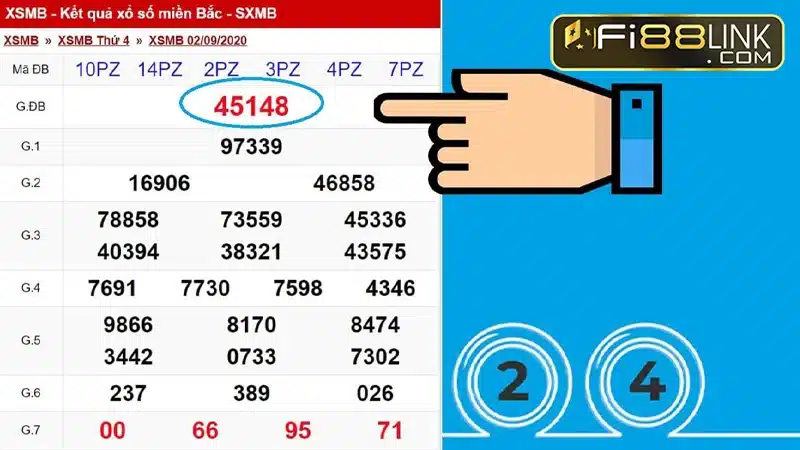

Một trong những kinh nghiệm bắt lô và phương pháp chơi hiệu quả đầu tiên mà bài viết muốn giới thiệu đến cho các anh em đó là, trùng đầu trùng đít ở giải 7. Chọn các số giải 7 từ kết quả xổ số, trong đó nếu trùng nhau thì lấy 2 số đầu của 2 giải giữa để ghép thành cặp lô trong 3 ngày tiếp theo.

Nuôi giải đặc biệt

Kinh nghiệm bắt lô và phương pháp chơi hiệu quả thứ 2 mà bài viết muốn bật mí cho anh em đó là nuôi giải đặc biệt. Với phương pháp cực kỳ đơn giản và dễ hiểu này, người chơi chỉ cần cộng tổng của các con số giải đặc biệt kết hợp với con số 0 hoặc con số 8. Anh em duy trì phương pháp này trong 3 ngày tiếp theo.

Đợi con lô nổ 3 nháy xuất hiện

Với phương pháp này hay còn gọi là soi cầu lô này là để nuôi. Với cách này anh em chỉ nên nuôi thêm tối đa 3 ngày, không nên theo nhiều ngày. Nếu anh em đánh đến ngày thứ 3 theo cách này mà lô vẫn chưa về thì anh em nên bỏ, không nuôi cho những ngày tiếp theo. Để tránh rủi ro và tổn thất do các khiếu nại lớn.

Chơi lô ngược lại kiếm 3 điểm

Muốn ăn ngay không cần nuôi, hôm nay về 3 lần thì ngày mai phải đánh ngược lại

Thủ thuật đánh loto kẹp

Thông thường trong bảng kết quả xổ số có rất nhiều loại kẹp số, các anh em để ý thấy những con nào kẹp giữa hai số 1 hoặc hai số 0, hai số 8 thì ta đánh cặp. Các anh em nên theo số đó trong 3 ngày là ăn, thường thì hay ra vào ngày thứ 2

Đánh lô bị lộn

Một trong những kinh nghiệm bắt lô và phương pháp chơi hiệu quả tiếp theo đó là đánh lô bị lộ. Với phương pháp này anh em chỉ nên theo 3 ngày đầu, không nên nuôi quá lâu bởi nó xảy ra quá nhiều rủi ro.

Đánh lô đề trực tuyến trên website uy tín

Nếu anh em muốn được tham gia chơi các trò cá cược đỏ đen như thế này, nhưng không có đủ điều kiện chơi ngoài đời thực. Anh em vẫn có thể chơi trên trực tuyến thông qua những website uy tín và chính thống.

Phương pháp đánh lô đề đơn giản và hiệu quả nhất

Sau khi tìm hiểu đầy đủ các khái niệm, hướng dẫn chơi lô đề với kiến thức cơ bản thì bài viết sẽ giúp cho anh em nghiên cứu một vài kinh nghiệm bắt lô và đặc biệt là phương pháp chơi hiệu quả nhất tại các trang web đánh lô đề. Anh em có thể sử dụng luân phiên các chiến thuật này một cách phù hợp nhất để tăng tỷ lệ về đích cho mình.

Chơi dàn lô đề theo phương pháp nào?

Tỷ lệ thắng khi tham gia chơi tại các nhà cái trực tuyến là 1-99, còn đối với những anh em đăng ký số truyền thống thì sẽ là 1-70 hoặc 1-80 (tùy khu vực). Do đó, anh em có thể áp dụng chiến thuật đánh nhiều con số cùng lúc trong ngày để tăng khả năng trúng thưởng ở mức cao nhất.

Phương pháp đánh đề dựa vào con đề về ngày hôm trước

Những người đã trúng lô kết quả hôm trước nhìn chung rất khó về vào ngày hôm sau. Tuy nhiên, anh em hoàn toàn có thể “bóc” con số này và đưa vào các hệ thống phân tích để nghiên cứu xem con số này có khả năng về vào ngày hôm sau hay không.

Con số này thường rất có khả năng giúp anh em giải quyết những vấn đề trong ngày hôm sau với tỷ lệ thành công rất cao. Có rất nhiều người đi trước đã áp dụng phương pháp soi cầu lô này và gặt hái được một số thành công nhất định nên anh em hoàn toàn có thể cân nhắc đầu tư.

Phương pháp đánh theo công thức tổng giải đặc biệt

Áp dụng công thức tính tổng giải đặc biệt về ngày hôm trước sẽ giúp anh em chọn được cầu lô, con lô cho ngày hôm sau. Công thức này cũng đơn giản đến mức anh em có thể áp dụng dễ dàng.

Ví dụ: Ngày hôm nay giải đặc biệt số 47271 thì anh em có thể chơi theo công thức 4 + 7 + 2 + 7 + 1 = 21 => Đánh song thủ lô 12 – 21 cho ngày hôm sau.

Tỷ lệ thành tiền cũng phụ thuộc vào con nào đẹp hơn và có tỷ lệ thành công cao hơn, anh em nên chú ý vấn đề này để tối ưu số tiền lãi cho mình.

Phương pháp đánh dựa vào giải 7

Đối với các anh em cược thủ chuyên nghiệp thì kinh nghiệm bắt lô và phương pháp chơi hiệu quả bắt đề giải 7 đã không còn mấy xa lạ nhưng lại có khá ít anh em tân thủ biết về cách đánh đề này.

Đừng bỏ qua những dữ liệu có được từ giải 7 trong kết quả xổ số của ngày hôm trước, để sử dụng chúng cho việc phân tích và bắt lô đánh cho kỳ lần này nhé.

Phương pháp chơi lô theo bạc nhớ

Theo các chuyên gia, anh em có thể đánh giá về trình độ của một cao thủ dựa vào bề dày kinh nghiệm của người đó.Một tay cá cược dành nhiều thời gian để đánh cũng như nghiên cứu và phân tích lô đề trong nhiều năm chắc chắn sẽ có rất nhiều kiến thức về bạc nhớ kỉ niệm.

Anh em có thể áp dụng cách chơi này cho:

- Phân tích bảng kết quả xổ số kỳ trước và các kỳ xổ số đã qua để dự đoán cho kỳ quay sắp tới.

- Đối chiếu kinh nghiệm bắt lô và phương pháp chơi hiệu quả bản thân để tìm ra các cặp lô đề nào có khả năng nổ cao nhất.

- Biết các cặp lô đi liền nhau để tăng khả năng ra 2-3 nháy cùng lúc.

- Áp dụng thành thạo các phương pháp trò chơi như lô câm, lô gan, lô ra theo lô, lô nổ nhiều nháy, tần suất và cuối cùng là chu kỳ đi của bộ số,…

>>Xem thêm: Đề về 18 hôm sau đánh con gì?

Kết luận

Trên đây, bài viết đã cung cấp những kinh nghiệm bắt lô và phương pháp chơi hiệu quả được nhiều cao thủ áp dụng và đã thành công. Hy vọng với những chia sẻ trên đã mang đến cho anh em nhiều may mắn. Chúc anh em sẽ thành công và kiếm được nhiều lợi nhuận từ những con số này nhé.